MATREX is part of the French companies associated with the French Fab, which represents the French industrial sector with common objectives. The French Fab includes French companies, economic actors, institutions, and industrial sites. They share the determination to develop the French industry and the entire supply chain.

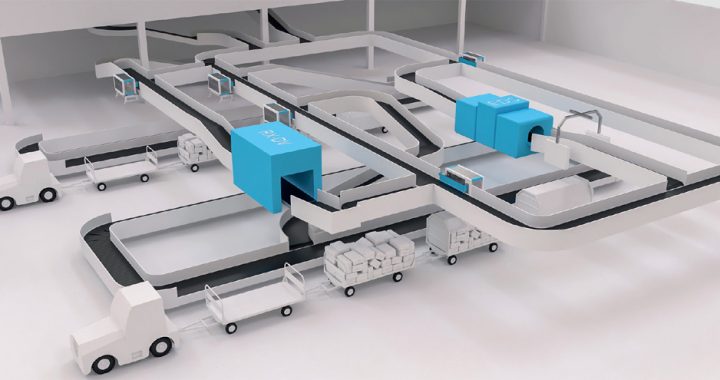

For over 60 years, MATREX has developed a unique expertise in the field of handling and has been established in the Burgundy region for 50 years. They design, manufacture, and install conveyors, handling systems and baggage handling systems. These equipment are intended for:

- Manufacturing industries (food processing, automotive, wood and furniture, waste treatment…)

- Logistics (parcel, order picking…)

- Airport sector (baggage handling, passenger handling, furniture…)

Our equipment is designed by our designers and manufactured exclusively in France by our workshop teams and using our own technical resources. Our strength lies in offering robust and high-quality equipment to our customers. Our constant concern is to improve and adapt our equipment to meet the expectations and needs of our customers. Therefore, we support them in the realization of their projects, from design to commissioning on their site.

The French Fab promotes French companies as much as possible. 95% of our suppliers are French companies. Our goal is to go even further by choosing regional and local suppliers. This is to preserve French know-how, proximity, and maintain a human and trusting relationship.

The French Fab also emphasizes the importance of human within the business and the company. We believe that the added value of our company primarily comes from the individuals who compose it. Working conditions, safety, and the well-being of our employees are our main concerns. We attach great importance to integration within the company, allowing new employees to discover all services from the outset. For us, this is the key to the success of the initial investment in MATREX, which is the human being and consequently their development.

MATREX’s policy is always to help its employees progress, particularly through training. That is why we have more than 1% of our budget to the training plan. The objectives are to acquire and develop new skills, be more versatile, and evolve towards new professions.

We also strive for minimal ecological impact on the world. We work towards reducing our carbon footprint through shorter transportation, resulting in lower greenhouse gas emissions. We also contribute to optimizing paper and plastic consumption, adopting reasonable energy consumption, and working with suitable supply chains for our packaging wood.

We apply this principle every day in our company. MATREX systematically commits to optimizing consumption and reducing waste in terms of raw materials, fluids, and energy in our own developments and investments. We aim to be a virtuous company in reducing our energy footprint in all aspects of our business. This vision is implemented in project designs for our clients, as well as in our internal manufacturing and organizational activities. It is also reflected in the rigorous management of our waste through approved channels and, above all, in waste minimization.